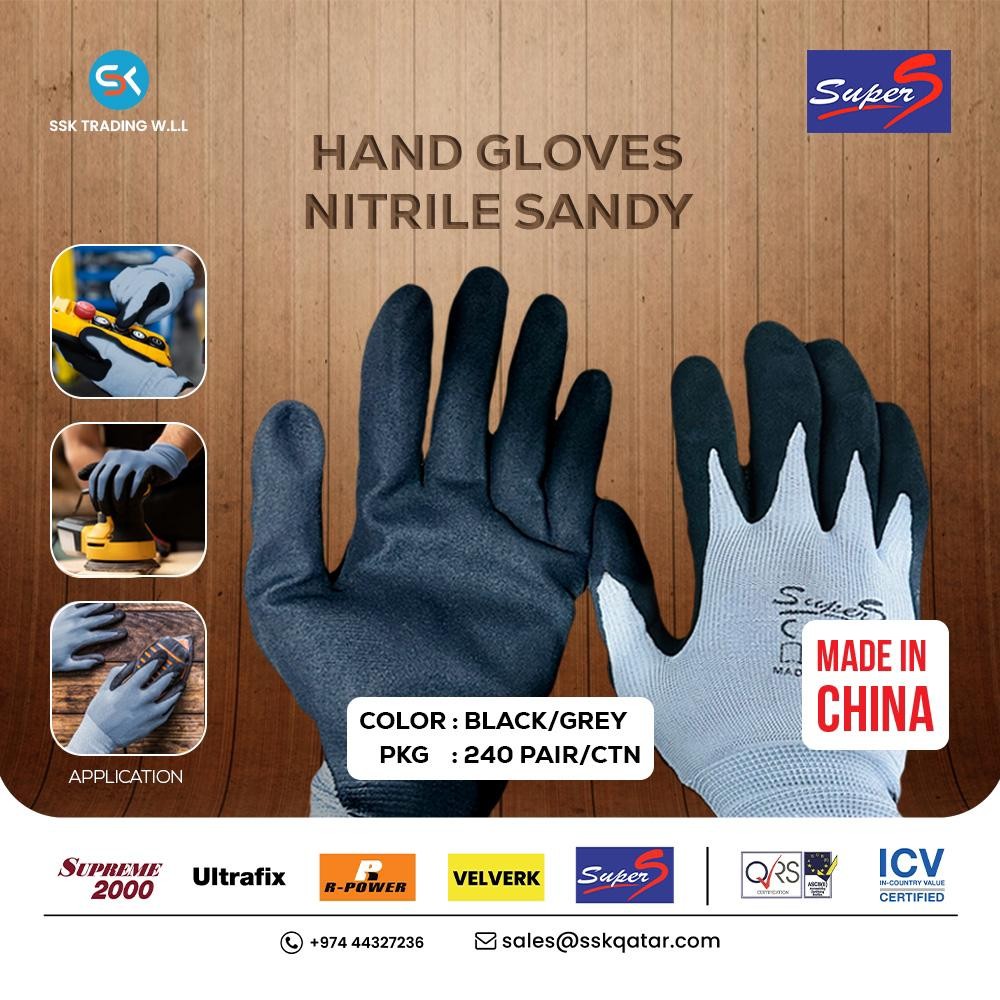

SuperS Cut Resistent Gloves Nitrile Coated Sandy

QAR 3.00

The SuperS Cut Resistant Gloves Nitrile Coated Sandy are designed to provide superior protection for your hands in demanding work environments. These gloves offer a combination of comfort, durability, and cut resistance, making them ideal for a wide range of applications. As a reliable Sandy nitrile gloves supplier in Qatar, we provide top-quality cut resistant work gloves like the SuperS Cut Resistant Gloves Nitrile Coated Sandy, trusted by professionals across various industries for their excellent grip, long-lasting performance, and high safety standards. Product features

They offer superior hand protection with high-level cut resistance, durable nitrile coating, comfortable fit, and breathability. They are ideal for various industries, ensuring safety and comfort during demanding tasks.

FAQ

FAQ — Cut-Resistant Gloves Nitrile Coated

1. What are cut-resistant nitrile-coated gloves?

These are protective gloves that combine a cut-resistant liner (often made from materials like HPPE, steel filament, glass fibre, or similar) with a nitrile coating on the palm or fingers to improve grip, abrasion resistance, and protection in oily or wet conditions.

2. What standards and ratings should I look for?

Important standards include EN 388:2016 (which tests for abrasion, cut, tear, puncture, and sometimes ISO cut test or TDM cut), and ANSI/ISEA 105 for cut levels in the USA. Look for cut levels (e.g. EN levels 3-5, or ANSI A2-A6) depending on your risk. Example: gloves with EN 388: 4544C or EN 388 4X44D. :contentReference[oaicite:0]{index=0}

3. How does nitrile coating help?

Nitrile coating adds benefits such as enhanced grip (especially in wet or oily environments), resistance to oils, better abrasion resistance, and sometimes better puncture protection in palm areas. It also improves durability of high-wear zones. :contentReference[oaicite:1]{index=1}

4. What gauge or liner thickness is typical?

Liners are often seamless knit, between **13-gauge** to **18-gauge**, depending on desired balance between dexterity and protection. Thinner gauges give more flexibility; thicker liners give better protection. Example: 13-ga liners in Mallcom P55, WORKSafe gloves. :contentReference[oaicite:2]{index=2}

5. Are these gloves reusable, washable, or one-time use?

Most cut-resistant gloves with nitrile coating are reusable. Many are washable (depending on manufacturer guidance) without significant loss of protection, though frequent washing or exposure to harsh chemicals can degrade the nitrile coating. :contentReference[oaicite:3]{index=3}

6. What are the limitations?

Even with cut resistance, nitrile coated gloves do *not* make you invulnerable. They may not protect well against high-temperature heat, molten metal, flame, or very high energy cuts. Also, extended exposure to aggressive chemicals can degrade the coating. Always check the glove’s rating, applicability, and inspect before use.

7. How should they fit / how to choose the right size?

Gloves should fit snugly enough that there is minimal slack in fingertips, but not so tight that they reduce blood flow or dexterity. Consider size, cuff style (knit wrist, extended cuff), liner material, and feel in grip. If possible test with your specific task (sharp edges, oily surfaces). Many manufacturers use colour coded binding or size markings. :contentReference[oaicite:4]{index=4}

8. When should gloves be replaced?

Replace gloves when you see visible wear: worn-through liner, cracked or peeled coating, reduced grip, frayed material, or when comfort (fit) deteriorates. Also after any cut penetration or damage that compromises integrity.

Applications & Use Cases

Applications & Use Cases — Cut-Resistant Gloves Nitrile Coated

- Metalworking & Fabrication

- Handling sheet metal, sharp edges, cut or bent metal parts

- Grinding, cutting, deburring operations

- Assembly lines with exposure to sharp tools or components

- Maintenance of metal structures and machining work

- Automotive, Glass & Ceramics

- Working with glass panels or cut ceramic tiles

- Automotive body work, stamping, sharp trim handling

- Handling of glass containers, bottles, edges

- Ceramic tile or mosaic work with sharp fragments

- Industrial Material Handling & Logistics

- Palletising, loading/unloading metal parts or sharp crates

- Handling sharp packaging straps, wires, or fibreglass boards

- Working in oil or slightly wet environments where grip is needed

- General purpose tasks with risk of laceration around edges

- Construction & Building Maintenance

- Roofing, metal roofing sheets, flashing, window frames

- Carpentry with occasional sharp tools or nail-edges

- Glass installation, glazing work

- Demolition tasks with debris containing sharp materials

- Oil & Gas / Heavy Engineering

- Pipe fittings, flange edges, sharp fittings

- Maintenance in oily, greasy work zones—nitrile helps with grip

- Sharp metal edges from parts, tools, machinery housings

- Operation of press tools or equipment that cut or shear parts

Product Features

Product Features — Cut-Resistant Gloves Nitrile Coated

- High cut resistance liner — made from HPPE, steel filament, glass fibre, or equivalent composite material to meet EN 388 cut levels 4-5 or ANSI A2-A4 or higher. :contentReference[oaicite:5]{index=5}

- Nitrile palm or partial coating — smooth or sandy nitrile applied on palm, fingers, and sometimes thumb reinforcement to enhance grip, abrasion, and oil resistance. :contentReference[oaicite:6]{index=6}

- Seamless knit liner — for comfort and dexterity; avoids seams that may catch or tear. Typical gauges are 13 to 18, depending on protection required. :contentReference[oaicite:7]{index=7}

- Thumb crotch and high-wear zone reinforcements — these areas often fail first; reinforcement improves durability and lifespan. :contentReference[oaicite:8]{index=8}

- Comfort features — good fit, knit wrist or extended cuff, breathable liners, lightweight design to reduce fatigue during long tasks. :contentReference[oaicite:9]{index=9}

- Grip in wet / oily conditions — sandy finish or texture on the nitrile coating to repel oil and moisture and provide secure handling. :contentReference[oaicite:10]{index=10}

- Durable construction — double stitching, robust cuff, reinforced parts (fingertips, palm) to prolong service life. :contentReference[oaicite:11]{index=11}

- Certification & labelling — clearly marked with EN 388 (and/or ANSI / ISEA), cut level, size, manufacturer; compliance with PPE regulations. :contentReference[oaicite:12]{index=12}

You must be logged in to post a review.

Related Products

-

QAR 50.00

-

QAR 4.00

-

QAR 35.00

-

QAR 69.00

-

QAR 150.00

-

QAR 40.00

SSK Trading WLL is a leading manufacturer and supplier of Personal Protective Equipment (PPE) in Qatar. We also offers a wide range of Building Materials and Construction Supplies, Cleaning and Maintenance Products, Adhesives, Sealants, and Tapes, Tools and Hardware, and Traffic Control Equipment making us a one-stop destination for industrial and commercial needs.

Product Categories

Shop links

Support

+974 4451 6044

sales@sskqatar.com

Reviews

There are no reviews yet.